Automatic gummy pill filling and counting machine

gummy pill filling and counting machine

production capacity:20-40 bottle/min

filling accuacy:±0.5%

air pressure demand:0.6mpa 3.5L/min

power source:110V/220V 50Hz 0.6kw

overall dimension1800*1800*1600mm

weihgt:250KG

Inquiry Now

Specification

| Production capacity | 20-40 Bottle/min |

| Applicable range | Pills less than 20mm in diameter Compatible with 0-5 size capsules Softgel capsules Diameter 5.5mm - 22mm vegetarian tablets Shaped tablets, sugar-coated tablets |

| Filling accuracy | ±0.5% |

| Air pressure demand | 0.6Mpa 3.5L/min |

| Power source | 110/220V/50HZ 0.6KW |

| Overall dimension | 1800×800×1600mm |

| Weight | 250KG |

Descriptions

PRODUCT DESCRIPTION

This is an automatic filling candy, pill machine, you do not need to worry about the output, precision technology, high efficiency, you can maximize the economy.

Advantage introduction

1.Accurate counting to ensure the same quantity in each bottle.

2.Fast speed and high output, the quantity completed in one minute is 30-40 bottles.

3.Save manpower, fully automatic, intelligent and efficient.

Details

This is the vibrating channel, the purpose is to sort the gummy, and finally put it into a large hopper for canning.

This is the details of the vibrating channel without candies. It is the fold type of Chen Bo, which is convenient for the separation of candies, so that they form channels separately and will not stick together.

This is where the candy is filled, and the four rods below are used to adjust the width of the channel, depending on the body of the bottle, and then to adjust the width. The amount of filling particles can be adjusted, and finally can be adjusted precisely to ensure the same amount in each bottle.

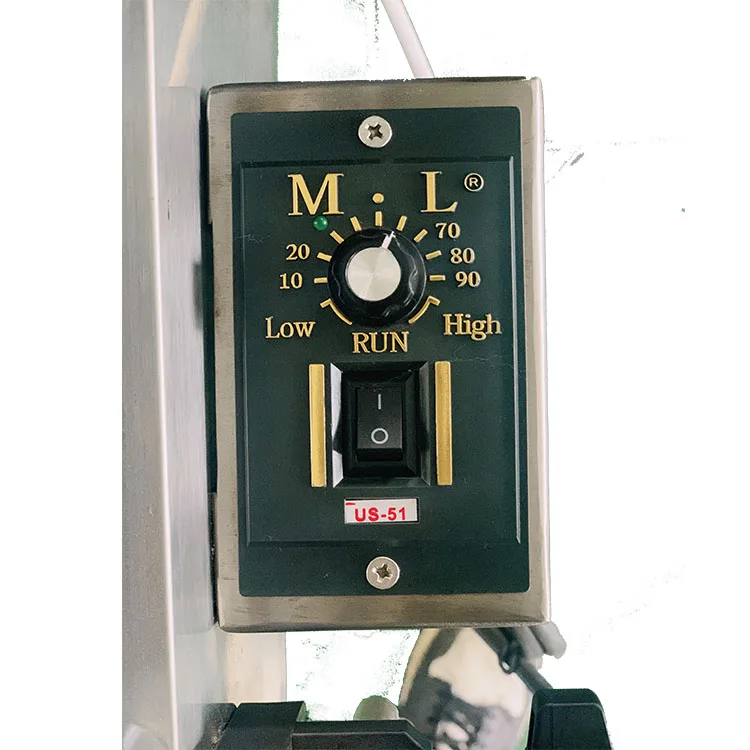

This is its switch. It has an adjustment range from 0 to 100 to control the speed of its work. You can adjust it to the range you want according to your own situation.

OPERATION

First click "Start" on the control screen, the machine starts to operate, and the candies are sorted on this vibration channel, and then sent to a hopper. Firstly, the bottle filled with candy is run on a stable and reliable conveyor belt, and then the bottle is accurately positioned by the induction cursor, and is transported to the filling position. adjust. It is precisely counted, and the number of candies in each bottle is the same.

FAQ

Q1:What's the filling speed?

A: It's 35-60 pcs/min.

Q2.How long is the warranty?

A: 1 year.

Q3.Delivery time?

A: About 30 days for production.

Q4.What's the MOQ?

A: Our machines can be customized to suit your needs, starting with one.

Q5.Why choose us?

A: Because LOM focus on improving the quality of the production and after-sales service.

Related Products

Please give us a message for your enquiry . order or advice. Thanks a lot.

Send Message